B-RP-100001 PEEK 1/4-28UNF Compact Flanged Fitting - 1.6mm OD Ferrule Set

Set consisting of:

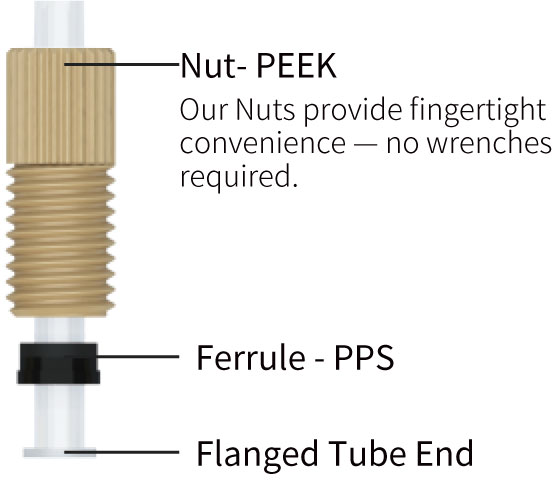

- B-RP-400001-PK-NA - Peek Compact Nut 1/4-28UNF - PEEK

- B-RP-200001-PS-BK - Ferrule 1.6mm OD - PPS

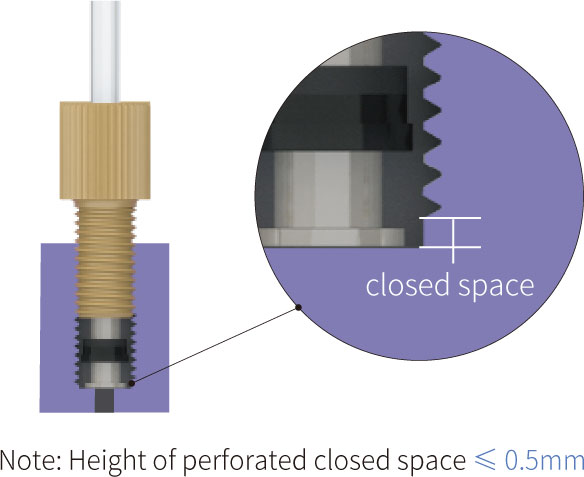

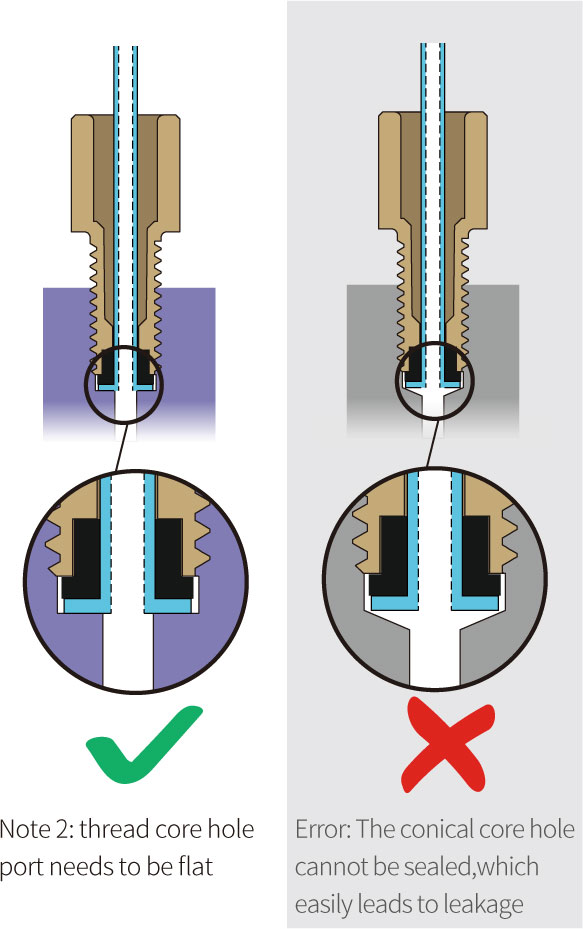

A traditional flat-bottomed compact fitting. The deformed tube end is compressed in the thread by the ferrule and the PEEK connector, so that an airtight connection is achieved.

- No change in tube diameter

- No effect on flow rate

- More stable flow rate

- Can be disassembled repeatedly without affecting its sealing

- Long-term working temperature range -50°C to +150°C

on stock

Only %1 left

Article no

B-RP-100001

$ 7.47

| Article no | B-RP-100001 |

|---|---|

| Connection thread male 1 | 1/4-28 UNF |

| Tubing size | 1.6 |

| Material | PEEK natural & PPS black |