dPOFLEX-PFS 4- Peristaltic Pumps Micro-volume Filling System - Dispensing System

Can be used independently as a small benchtop filling system, or integrated into semi-automatic systems or fully automated systems.

Precise filling of micro-volumes from 30 μL, accuracy better than ±1%.

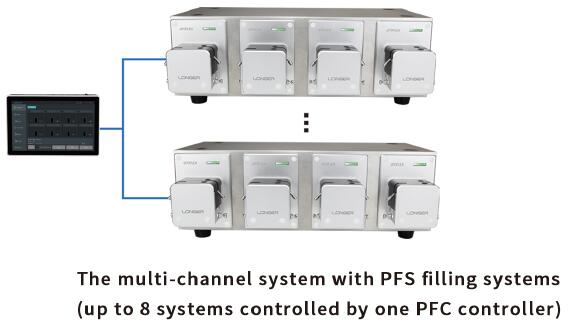

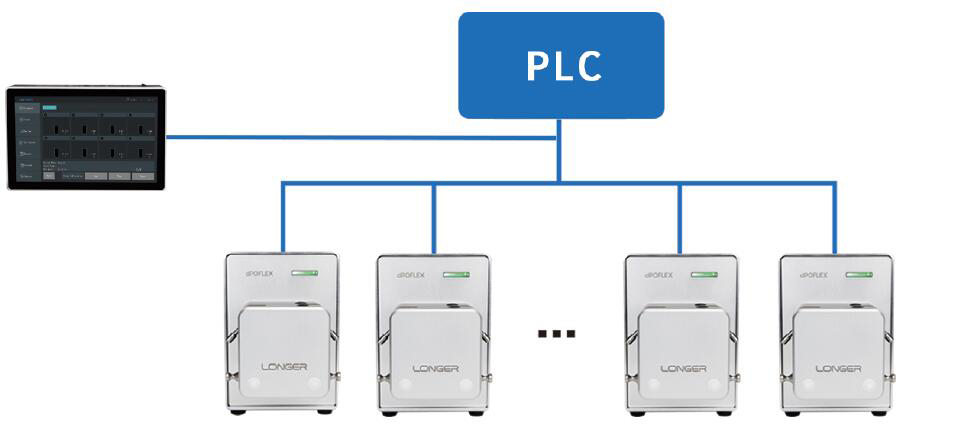

The master controller (7" touchscreen controller - needs to be ordered seperatly) can control up to 32 pump systems, which can be set with individual parameters.

Three levels of user accesses, operation log, batch report with electronic signature, for FDA 21CFR Part 11 compliance.

Micro-volume filling with high precision and efficiency to prevent costly overfilling

- Precise filling of micro volumes as low as 30µL

- Filling accuracy better than ±1%

- High flow rate up to 16mL/s

- High Efficiency up to 120 bottles/minutes/channel

7-inch high-resolution touchscreen

Powerful functions, flexible configuration, and easy-to-use (needs to be ordered seperatly):

- Intuitive graphic interface for a fantastic interactive experience

- Up to 500 recipes can be stored and recalled easily

- Three levels of user accesses(administrator, developer, operator), operation log, batch report( can be saved to USB flash drive or printed directly), and electronic signature, for GMP and FDA 21CFR Part 11 compliance

Control of multiple pump units

The master controller can control multiple units which can be set with individual parameters

- One PFC controller can control up to 32 channels

- In multi-channel system, each channel could be set with the same parameters or individual parameters

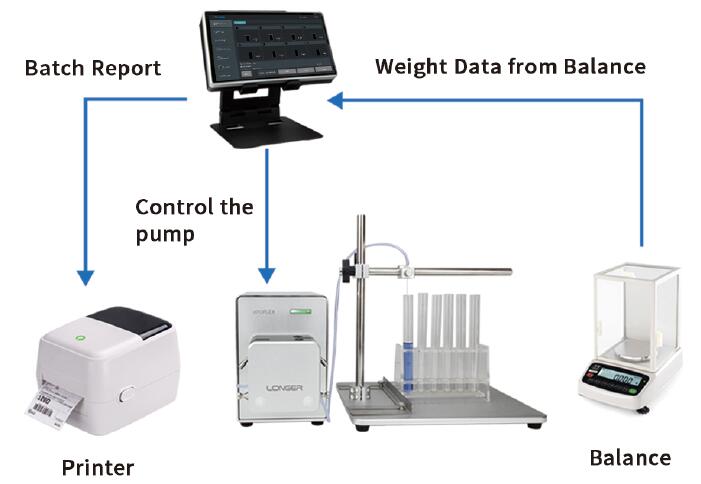

Calibration modes - semi automated

A variety of calibration modes to improve calibration efficiency and ensure filling accuracy

- The PFC controller can automatically read the filled weight from a compatible balance

- The on-line calibration can be performed during the operation (95%-105% calibration range)

Semi-automatic & fully automated filling systems

Filling unit PFU and system PFS can be integrated into semi-automatic systems or fully automated systems

- PFU can be remotely controlled via RS485 interface with Modbus RTU protocol

- PFS can be remotely controlled via RS485 interface with Modbus RTU protocol or Ethernet with TCP/IP protocol

- Interfaces for start input, stop input, disable drive input, and malfunction status output, enable the automatic system integration

dPOFlex PFU Accessoires

High-quality accessories help build a tabletop intelligent dispensing system

- Silicone tubing compliant with USP requirement

- Filling stand for different vials, bottles, or microtubes

- High-precision filling probe

- Footswitch

Technical Specifications

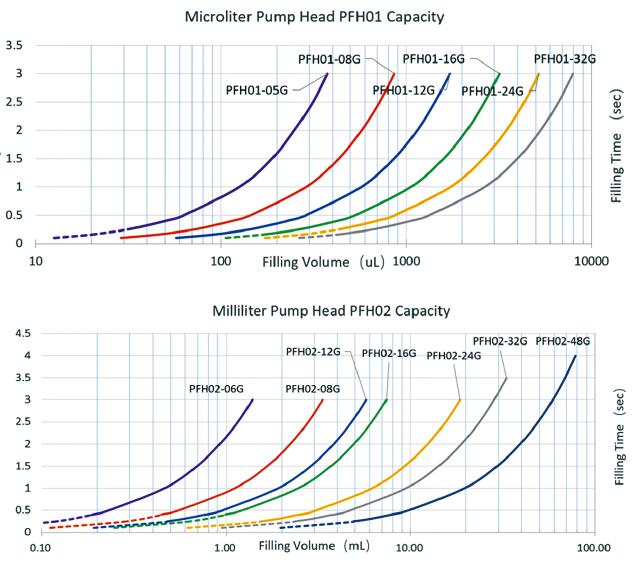

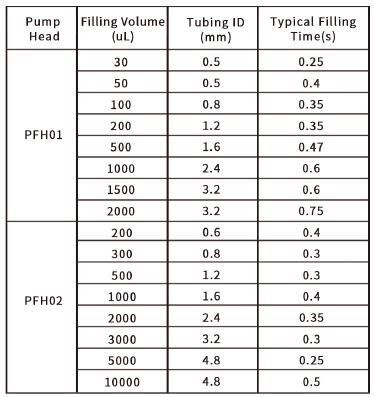

| Pump heads | PFH01(microliter pump head), PFH02 (milliliter pump head) |

| Tubing | Silicone tubing and tubing kits |

| Filling volume | 1µL-99.99L |

| Filling accuracy | better than ±1% |

| Filling precision | CV<0.5% |

| Filling time | 0.1seconds-999.9hours |

| Filling cycle | 0-999999 (0 means unlimited) |

| Interval time | 0.1s-999.9s |

| Back suction parameter | 0-30 |

| Working direction | Clockwise |

| Calibration | Manual input calibration, balance reading calibration or online ratio calibration, with volume or mass data |

| Display | 7 inch touch screen, Chinese or English can be set |

| Work mode | Single channel filling, multi-channel filling with the same parameters or individual parameters |

| Access management and password protection | Three levels of user accesses (administrator, developer, operator), each user can have an exclusive password |

| Parameter recipe | Up to 500 recipes can be stored and recalled easily on the PFC controller |

| Batch report | Up to 800 batch reports can be stored on the PFC controller, which can be saved to USB flash drive or printed directly |

| Communication control | RS485 interface, Modbus RTU protocol |

| External control input | Start the pump, emergency stop, disable channel |

| Output | 1 output for malfunction status |

| IP rating | IP32 |

| Power supply | AC 100V-240V ,50/60Hz, 250W |

| Dimension(L*W*H) | 548mm×245mm×198mm(without pump head) |

| Weight of system | 16.1kg(without pump head) |

| Dimension of controller (L*W*H) | 187mm×123mm×39mm |

| Weight of controler | 0.6kg |

| Working condition | Temperature: 5 - 40°C ,RH: ≤85%, no condensation |

| Storage and transportation condition | Temperature:-40 - 70°C,RH: ≤85%, no condensation |

Pump heads

| Roller Material | Roller Material | Roller Number | Speed (rpm) | Tubing ID (mm) | Max Flow Rate (mL/min) | Recommended Filling Volume | Max Filling Volume per Second | Recommended Filling Nozzle ID |

| (Accuracy≤±1%) | (mm) | |||||||

| Microliter Pump Head PFH01 | Stainless Steel | 12 | ≤350 | 0.5 | 7 | 30μL | 118μL | 0.3 or 0.6 |

| 0.8 | 17 | 42μL | 269μL | 0.6 | ||||

| 1.2 | 34 | 90μL | 534μL | 1 | ||||

| 1.6 | 63 | 132μL | 987μL | 1 or 1.6 | ||||

| 2.4 | 104 | 400μL | 1.6mL | 1.6 | ||||

| 3.6 | 159 | 760μL | 2.47mL | 1.6 or 3.2 | ||||

| Milliliter Pump Head PFH02 | Stainless Steel | 8 | ≤450 | 0.6 | 27 | 0.2mL | 0.42mL | 0.6 |

| 0.8 | 66 | 0.4mL | 1.03mL | 0.6 | ||||

| 1.2 | 114 | 0.5mL | 1.78mL | 1 | ||||

| 1.6 | 147 | 0.8mL | 2.29mL | 1 or 1.6 | ||||

| 2.4 | 371 | 1.16mL | 5.77mL | 1.6 | ||||

| 3.2 | 566 | 2.15mL | 8.80mL | 1.6 or 3.2 | ||||

| 4.8 | 1178 | 3mL | 18.28mL | 3.2 or 4.5 |