Peek fittings & connectors for HPLC, GC and life science

Our PEEK fittings and connectors are a fundamental part of a variety of industries, from medical and pharmaceutical research to analytical chemistry and biotechnology. The connectors are a crucial component when it comes to precisely controlling and manipulating the flow of liquids and gases. Manufacturing the connectors from the high-performance thermoplastic polyetheretherketone (Peek) helps increase the overall efficiency, accuracy and reliability of the systems.

-

-

-

-

-

-

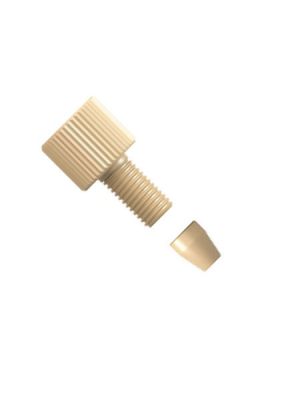

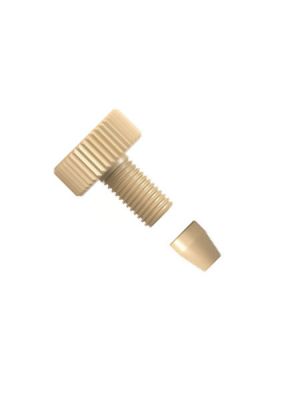

- Large Bore PEEK Flangeless Fitting — two-piece set - 5/16-24 UNF - 4.8 mm OD SKU:

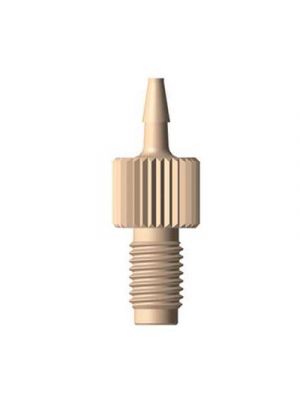

B-RP-108001As low as$ 13.13 - PEEK Fingertight Fitting Two-piece Knurl Head short - 10-32 UNF coned SKU:

B-RP-105006As low as$ 9.78 - PEEK Fingertight Fitting Two-piece Knurl Head compact - 10-32 UNF coned SKU:

B-RP-105002As low as$ 9.78 - PEEK 5/16” Hex Head Fitting Fingertight one-piece - 10-32 UNF conical SKU:

B-RP-104003-PK...As low as$ 3.43

Benefit from the advantages of our high-quality PEEK connectors

Chemical Compatibility: Peek connectors are highly resistant to a wide range of chemicals, including aggressive solvents and corrosive substances. This chemical compatibility ensures that fluidic systems can handle various liquids and gases without connectors corroding or leaking over time.

High Purity: Peek is known for its low extracts and releases, making it an excellent choice for applications where the purity of the liquid transported is critical. In life science industries such as medical technology, pharmaceuticals and biotechnology, Peek connectors help ensure that the fluid being transported remains pure.

Thermal Stability: Peek connectors can operate efficiently in a wide temperature range, from subzero to elevated temperatures. This property is invaluable in fluidic systems that can be subject to extreme temperature fluctuations during various processes.

Low outgassing: In high-precision applications, such as aerospace or analytical instrumentation, Peek connectors offer minimal outgassing. This is important to maintain a clean and controlled environment and prevent potential contamination of sensitive samples or equipment.

High pressure resistance: Peek connectors can handle high pressure fluidic applications such as chromatography (HPLC, GC), making them ideal for situations where maintaining system integrity under elevated pressure is critical.

Biocompatibility: In the medical and life science fields, Peek connectors are biocompatible, meaning they can be used safely in contact with biological fluids and tissues. This makes them a suitable choice for applications involving medical devices and diagnostic devices.

Mechanical Strength: Peek connectors have excellent mechanical strength and can withstand physical stress and maintain structural integrity over time. This is particularly important in fluidic systems that are subject to dynamic conditions or frequent connections and separations.

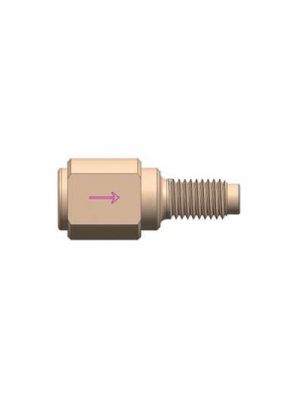

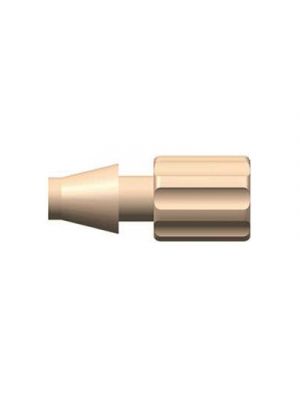

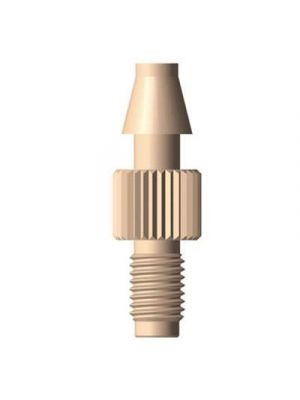

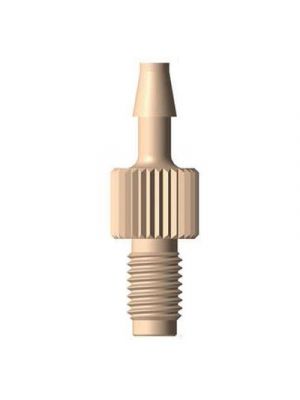

PEEK fingertight fittings with knurled heads

The knurled head is the distinctive feature of these fittings. It has a fine, rough structure that ensures better grip. This structure allows you to easily tighten or loosen the fitting with your fingers without using additional tools. This is particularly beneficial in laboratory environments where precision and ease of use are important.

Thanks to the knurled heads, the fittings can be tightened safely and quickly, even in narrow or difficult-to-access areas. The grip of the surface reduces the risk of slipping and ensures uniform tightening force, which increases the tightness of the connection.

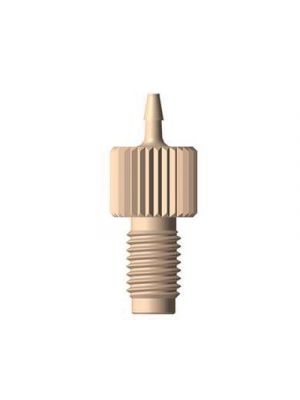

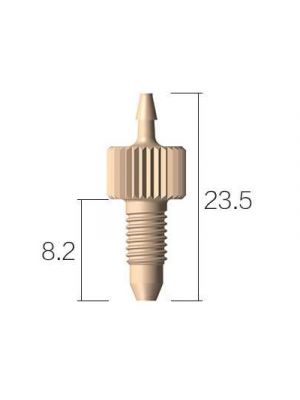

PEEK Check Valves for HPLC up to 700 bar

PEEK (Polyether Ether Ketone) check valves are essential components in HPLC systems and life science applications due to their chemical resistance, mechanical strength, and high-pressure tolerance. They ensure unidirectional fluid flow and prevent backflow in systems operating at pressures up to 700 bar. Various designs cater to different operational needs.

Valve Types:

Diaphragm Valves: Ideal for precise flow control with low dead volume, chemically resistant, and suitable for sterile environments.

Ruby Ball with Spring: Provides robust sealing and fast response due to the spring mechanism, perfect for high-pressure applications.

Ruby Ball without Spring: Simplified design without a spring, suitable for systems with stable pressure.

Duckbill Valves: Elastic, self-sealing, chemically inert, and suitable for dynamic pressure conditions.