Check Valves

Check valves are essential components in life science applications, ensuring unidirectional fluid flow and preventing backflow. They are used in systems where precise control of fluid movement is critical, such as in pharmaceutical, biotechnology, and medical industries. Depending on the application's requirements, check valves are made from various plastics that offer chemical resistance, mechanical strength, and sterility.

-

-

-

-

-

-

-

-

- Single Use Disk Check Valve 3.3mm Tube Stem - Polycarbonate Body SKU:

B-WC-0007Special Price $ 1.50 Regular Price $ 2.01 Discount 25% - Single Use Disk Check Valve, Luer Lock, Medical ABS SKU:

B-WC-0006Special Price $ 0.68 Regular Price $ 0.91 Discount 25% - Single Use Disk Check Valve Female Luer Lock, Cracking Pressure <= 8 mbar, Filtered, ABS SKU:

B-WC-0005Special Price $ 5.60 Regular Price $ 7.47 Discount 25% - Check Valve 3/32" (2.4mm) ID Tube - ABS Body - <= 8 mbar Cracking Pressure, Silicone Disc Polystyrene SKU:

B-WC-0004Special Price $ 1.65 Regular Price $ 2.19 Discount 25% - Check Valve 1/16" Barbed Ports - Polysulfone - < 10" H2O Cracking Pressure SKU:

B-WC-0003Special Price $ 18.64 Regular Price $ 24.85 Discount 25% - Single Use Disk Check Valve with 0.2µ filter - Barb to Luer Lock Male - ABS Body with Polystyrene & Silicone Disc SKU:

B-WC-0002Special Price $ 4.46 Regular Price $ 5.95 Discount 25% - Single Use Disk Check Valve Barb to Luer Lock Male - ABS Body with Polystyrene & Silicone Disc SKU:

B-WC-0001Special Price $ 1.58 Regular Price $ 2.10 Discount 25% -

-

-

-

-

-

-

-

-

-

-

- High Pressure PEEK Inline-Check-Valve with Spring - 1/4-28UNF - 1.5mm SKU:

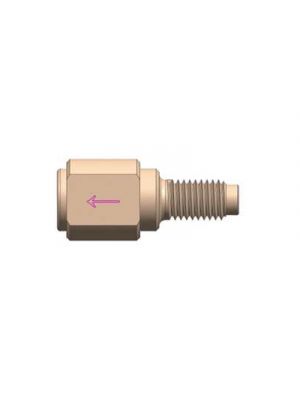

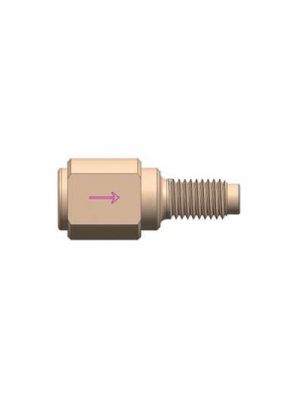

B-JC-400005-15...$ 108.36 - High Pressure PEEK Outlet-Check-Valve with Spring - 1/4-28UNF - 1.5mm SKU:

B-JC-400004-15...$ 108.36 - High Pressure PEEK Inlet-Check-Valve with Spring - 1/4-28UNF - 1.5mm SKU:

B-JC-400003-15...$ 108.36 - High Pressure PEEK Outlet-Check-Valve with Spring - 1/4-28UNF to 10-32UNF - 0.8mm SKU:

B-JC-400002-08...$ 108.36 - High Pressure PEEK Inlet-Check-Valve with Spring - 1/4-28UNF to 10-32UNF - 0.8mm SKU:

B-JC-400001-08...$ 108.36 -

-

-

-

Plastics for Check Valves:

-

PP (Polypropylene): Widely used for its chemical resistance and low cost. Suitable for less aggressive chemicals and moderate temperature applications.

-

ABS (Acrylonitrile Butadiene Styrene): Offers high impact resistance and moderate chemical resistance, ideal for applications where mechanical durability is more important than chemical aggressiveness.

-

PC (Polycarbonate): Known for its transparency and toughness, used in applications requiring visibility of the medium and structural strength.

-

PU (Polyurethane): A flexible material with high abrasion resistance, ideal for applications needing mechanical flexibility and elasticity.

-

PEEK (Polyether Ether Ketone): A high-performance plastic, extremely resistant to chemicals and high temperatures, suitable for demanding applications under high pressure and aggressive media.

-

PVDF (Polyvinylidene Fluoride): Highly resistant to chemicals and UV radiation, commonly used in environments with aggressive chemicals, such as biotechnology processes.

Types of Check Valves:

-

Duckbill Valves: Elastomeric valves with a flexible "duckbill" that opens under forward flow. They provide a simple, self-sealing solution with no moving parts, ideal for systems with variable pressure conditions.

-

Ball Valves with Spring: These valves use a ball as the sealing body, supported by a spring. The spring ensures quick and secure closure, making them ideal for high-pressure applications with rapid flow changes.

-

Ball Valves without Spring: A simpler variant where the ball is operated by the fluid pressure alone. These valves have fewer moving parts and are suitable for systems with stable pressure conditions.

-

Diaphragm Valves: Diaphragm-based valves offer precise and sterile flow control. The diaphragm prevents backflow, making them ideal for applications with sensitive fluids and strict hygienic requirements.

-

O-Ring Valves: These valves use O-rings as sealing elements, offering a simple yet effective sealing solution. They are available in various materials and can be adapted to the chemical resistance required for the specific application.

PEEK Check Valves for HPLC up to 700 bar

PEEK (Polyether Ether Ketone) check valves are essential components in HPLC systems and life science applications due to their chemical resistance, mechanical strength, and high-pressure tolerance. They ensure unidirectional fluid flow and prevent backflow in systems operating at pressures up to 700 bar. Various designs cater to different operational needs.